|

|

-

Bouncing the valves? Bouncing the valves?

looking for any suggestions/ past experience about this

We've been chasing an issue for a while now with loosing valve lash ( this time after only 3 laps).

I't happened on us with 2 different pairs of heads (RHS RR23, and Dart Iron Eagles), 2 different blocks (Dart and OEM 010) , 2 different cams (comp and now Jones both solid about .620 lift) Ti and or stainless, used 11/32 stems, 7mm stems. 5/16 stems, .600 long on the RR 23's to .100 long on the Darts, Valve brands have been Ferrea, Si, and Manley, all the same result, it beats the keeper groves up till it slips up the stem.

Different springs, keepers and retainers

Jesel shaft rockers, Jesel belt drive

good fuel, and only 32-33 degrees timing.

no tulip on the valves, it just beats up the valve grind angles till they ride a little deeper in the seat

completely frustrated

-

-

-

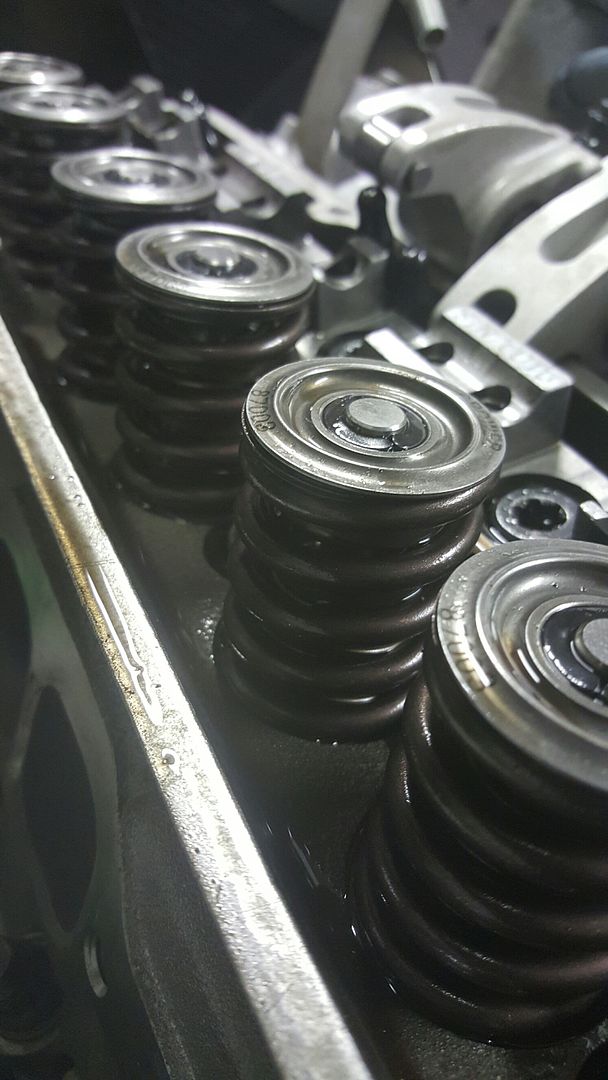

notice how much difference in how much of the valve tip sticks out of the keepers.

prior to running it for 3 laps, the valve tips were all consistent and up about .200 above the keepers.

now some are nearly flush with the keepers (1st pic) and several of the others are all over the place in how much they stick out

-

spring pressure is 130# on the seat, and 440# over the top

-

I showed one of our valves to a machine shop that it looked like the lock was starting to pull and he said that some keepers have a chamfer and some are square at the top. Take one of the springs off and show us the valve and keepers.

Last edited by powerslide; 09-04-2015 at 11:27 AM.

-

oh it did chew up the keeper groove on several.

the 2nd time we sent the valves back to Ferrea and they replaced several and touched up the others.

that was with the RHS raised runnner heads, this time its the same short block, but with Iron Eagle heads.

The machine shop set up the Jesel shaft rockers, and it only needed 1 .030 shim under the stand.

they are the square cut keeper grooves, which some folk dont like, but the machinist says thats not a legitimate argument, because they still use them on blown alcohol drag hemi's without issue.

-

I think the trouble comes if you use the chamfer keepers on the straight valves I might have that backwards.... Did they use the mid lift method to determine the shims or do you know how they came up with it?

Last edited by powerslide; 08-31-2015 at 03:53 PM.

-

It doesn't matter what its on or who put it together,if your floating the valves,its going to beat everything up.You can be floating the valves a lot earlier than what you think if you have really radical lobes.

-

what's the install hieght on the springs and the coil bind hieght and the actual lift at the valve?

What I'm getting at is, you are probably experiencing spring surge. You likely have way too much clearance from coil bind at the lift your running which is causing spring surge which is likely the source of the valve train unstability and most likely harsh valve bounce. This would explain the beat up seats and lock to valve groove issues.

Last edited by billetbirdcage; 08-31-2015 at 09:00 PM.

-

^^^ tell me more ! ^^^^ interesting, never heard of that.

I'll have to see what the installed height is from the machine shop, but I do remember him telling me that there was "plenty" of room before coil bind.

Should we run it at a minimum ? What is the minimum?

Solid flat tappet with 7800 chip rule

-

We typically try to keep guys on our springs between .060 and .100 from bind. depending on the application that changes slightly but for endurance applications like yours if you are too far from bind you definitely will have spring surge. You don't have enough seat pressure for your application, if it were me I'd have 150-160 on the seat. Whats your installed height and how much lash are you running?

-

I agree with what's been said so far, but even in valve float, or spring surge, your locks should NEVER climb up the valve stem, only way that can happen is if they are wrong for the valve or retainer. TB

-

I was incorrect on the spring pressures after I talked to him yesterday.

They are close to 150# on the seat, and 420# over the top.

But Mike Jones of Jones Cams suggested 160# on the seat, and to use 2 dial indicators and check lift at the lifter and retainer through the range of motion to see if the rocker ratio stays true the entire range

-

Hot lash is .018, but Mike also said we could tighten up hot lash .002 to .004 and see if that helps the condition

-

Originally Posted by TBRE

I agree with what's been said so far, but even in valve float, or spring surge, your locks should NEVER climb up the valve stem, only way that can happen is if they are wrong for the valve or retainer. TB

I gotta agree with tony, while it may be hard on the grooves and locks typically the valve will give up before the lock groove. By the part number on the retainers it appears to be a Crower 10 degree tool steel retainer, are you sure you have 10 degree locks and not super 7's or regular 7 degree locks? There is also conventional (square groove) and bead loc (round groove) so they have to have the matching locks to the valves.

The groove is more a location devise more then anything, the major holding of the valve is really supposed to be done by the collet effect of the angle interference fit of the retainer and lock, it's pinching the lock on the valve holding it.

I'm far from a professions engine builder, but I'd say you have at least 2 things going on. Wrong retainer/lock combo for the valves and most likely either spring surge from too much distance from coil bind or another valve train issue that is cause it to be extremely unstable.

Here is an old quote from Billy Godbold an engineer at comp cams on coil bind:

Godbold notes that "from high-speed video and testing, it is clear that adjacent coils contact as you approach the valvetrain limiting speed. Hence, modern springs are designed to run near coil bind and use the coil-to-coil interaction for improved damping at or near max lift. This interaction is one of the most effective means of dampening spring surge, but the valvespring must be properly designed in terms of solid stress to safely use this interaction." Depending on the intended use, the spring and cam-lobe design, and the engine builder's preferences, you will now see coil bind safety margins vary from as low as 0.015 inch to as high as 0.120 inch, with tighter numbers predominating on very stiff valvetrains. In a serious valvetrain, anything more than 0.150 inch can cause spring surge, which can greatly reduce the available spring load needed to close the valve.

locks/retainers:

The retainer must also be compatible with the valve lock angle. For years, valve locks were machined at a 7-degree angle of incidence. Comp Cams developed (and patented) 10-degree locks, which have a larger contact area that spreads the load over a greater surface area. For most performance work, the 10-degree configuration has pretty much become the industry standard.

But there are still some 7-degree proponents. SAM's Massingill maintains that the 7-degree lock puts greater clamping force on the valve. "The step on the inside of the retainer only locates the retainer to set the correct installed height; it doesn't actually hold the retainer in place. This is done by the clamping force of the spring pressure; as pressure increases, so does the clamping force." The so-called Super 7 lock (which is actually 8 degrees) may be the best of both worlds: Available from Manley and others, it has almost as much surface area as a 10 but the clamping force of a 7.

While the lock's outer angle must mate with the retainer, its inside shape must match the valve stem diameter and be compatible with the shape of the valve stem's retention groove. Different valve stem sizes will require corresponding locks. As for shape, traditionally, most U.S. domestic valves were machined with square keeper grooves. Motorcycles, imports, many late-model domestics, and now high-end custom valves often use a superior radiused beadlock groove. Less likely to propagate stress cracks, the radiused groove has no sharp edges and a greater contact depth-but the machining process is more costly. Consider beadlock retention mandatory for small-diameter valve stems (less than 5/16 inch) or with any titanium valves; it's also a good idea with larger-stem stainless valves or more-than-200-pound seat pressures if you need to order custom valves anyway.

-

Originally Posted by hogracer3d

^^^ tell me more ! ^^^^ interesting, never heard of that.

I'll have to see what the installed height is from the machine shop, but I do remember him telling me that there was "plenty" of room before coil bind.

Should we run it at a minimum ? What is the minimum?

Solid flat tappet with 7800 chip rule

You will have to check out the specs on install hieght for your heads but a comp 977-16 will generally put you around 150 seat and 440 open and have the right distance before coil bind on about a .600 lift cam, but it's been years since I used a flat tappet so who knows if the spring is the same as it was years ago. Least with the 977 10 years ago, set up that way with about .050 from bind they would run at 8300 RPM or more for 3 seasons and not lose pressure, we just replaced them cause they were old but never showed any signs of pressure loss and never broke one. Between the guys I knew running that spring combo, there was probably 50 or more engines that saw the same thing on spring life and never a failure.

But you know how things change, parts are not the same as they used to be so it's possible the source for the springs or the specs have changed. Do your own research before taking advise from someone you don't know (ME, LOL).

Search spring surge on youtube or google and you will find some video's of it showing what it does. If the machine shop your using doesn't know about this and the effects of being too far from coil bind: FIND ANOTHER MACHINE SHOP OR ENGINE BUILDER!

TBRE (Tony is pretty sharp) and plenty of others could likely fix your issue pretty quick.

-

I am actually a customer of Tony's but this stuff isn't his.

My machinist is the same one we've used for years, and way too smart of a guy to mismatch stuff.

Very thorough and meticulous .

just came back from there, and we've now seen some signs of detonation in a couple of cylinders, with 2 intake valves tuliped and .030 longer than they used to be, and 2-.018 longer

verified timing mark to be correct, checking fuel quality and delivery now

Springs are Comp 977-16 installed at 1.850

-

looking at the first picture you posted:

#7 exhaust the top of lock to valve tip appears to be around .100 or so

#7 intake appears to be .050 or so

See if all the intakes and exhaust are the same, or it's random between all the valves

Just from that a couple of obvervations.

1. Either it has 2 different locks on it, like a +.050 install hieght lock on one and a STD on the other

2. Maybe it has same height locks but since the thing has been beating up the seats so the valve seat depth is way off to each other and someone to set the stem hieght for the Jesel has to remove a lot of material from the intakes. Like someone didn't set the valve depths on the valve seats and they are all random depths and just ground the stems to get the stem height correct.

3. 2 different valve brands with different dimensions from groove to valve tip

4. Retainers different from one valve to another as the part number shows that to be a +.085 install height retainer. I can't see the exhaust retainers part number but maybe it's a non drop retainer.

I have gotten miss packaged stuff before like a set of 11/32nd locks that had one 3/8 lock in it, it's easy to miss. Also I really don't trust miss matching part brands on locks and retainers, I have often found that the angles don't match sometimes, like retainer being a 10.5 degree and a different brand lock being a 9.5 degree. You can also get one/several +.05 lock/locks in a std set or vice versa. It's easy to miss, I got a set of assembled AFR heads for a customer that had one half a 3/8 lock on one valve so it happens.

I know they changed the install hieght on the 977 from 1.800 to 1.850 years ago, I used them at 1.800 which was 160 on the seat and with a .600 lift cam minus the lash it was around .060 from coil bind. So depending on your actual lift numbers at the valve (remember it won't be exactly what the card says cause you have rocker and push rod flex so it's not uncommon to lose upwards of .04 lift in some cases - doubtful in your case but more like maybe .010) your probably not horrible on the coil bind, but I would check it and see where your at. Also check the actual bind of the springs, not what is listed in the book as it's usually off a fair amount.

Good luck

Last edited by billetbirdcage; 09-01-2015 at 03:33 PM.

-

thanks,

all the valve tips prior to running hot laps were a good bit further out of the keepers, and were all similar looking height wise.

now the #7 intake is not far from flush with the keepers, and the rest are all over the place.

I could see them possibly being different brand stuff, or maybe being misboxed or something.

we've had to get all new intake valves now because the grooves and valve angled are beat beyond touch up.

but I don't know the details on the brand and such, I do know that those retainers are 10 degree, and the grooves are conventional square cut

he showed me today that a couple of the intake valves are tuliped and .030 longer than the others because of it, and the valve angles show a big groove in them from contact with the seat

so our feeling is that we are chasing 2 problems, Detonation, and some keeper issue.

he was familiar with spring surge, but he said his experiance (largly drag racing ) with it was mostly with roller cam set ups

Last edited by hogracer3d; 09-01-2015 at 05:16 PM.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

All times are GMT -5. The time now is 10:47 PM.

|

|

Senior Member

Senior Member

Bouncing the valves?

Bouncing the valves?

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Junior Member

Junior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Reply With Quote

Reply With Quote

Bookmarks