|

|

-

Bump Stop Help Bump Stop Help

So I've gotten a 300# spring and a 2" afco christmas tree bump stop to put on the RF of my blue / gray rocket.

Is there more to mounting the bump stop than sticking it on the shaft and moving on ? Does it just ride on the lock nut / spring cup , or is there something that's supposed to go below the bump stop itself to ride on ?

If I'm getting in to any crazy secrets, feel free to PM and thanks a bunch for any help.

-

I ran mine strait on the spring seat on the bottom and a aluminum washer with a bronze bushing on top. my washer came from RE suspension , but I think afco has them now..

-

Originally Posted by fastford

I ran mine strait on the spring seat on the bottom and a aluminum washer with a bronze bushing on top. my washer came from RE suspension , but I think afco has them now..

Thanks for the reply .. what's the bronze bushing and the washer for ? Seems like the shock would just compress straight down to the top of the bump stop.

Also, how do you determine what the height of the bump stop should be .. or is that part of the magic ?

Last edited by RacerX10; 03-30-2016 at 05:28 PM.

-

Originally Posted by RacerX10

Thanks for the reply .. what's the bronze bushing and the washer for ? Seems like the shock would just compress straight down to the top of the bump stop.

Also, how do you determine what the height of the bump stop should be .. or is that part of the magic ?

Take COT bump, get peanut butter, fill with peanut butter, give to your dog as a new Kong toy....problem solved..... It's best to use in a cup set cup on top of machine washer and using a washer on top of COT bump and use packers to adjust but in all honestly throw it away to progressive

-

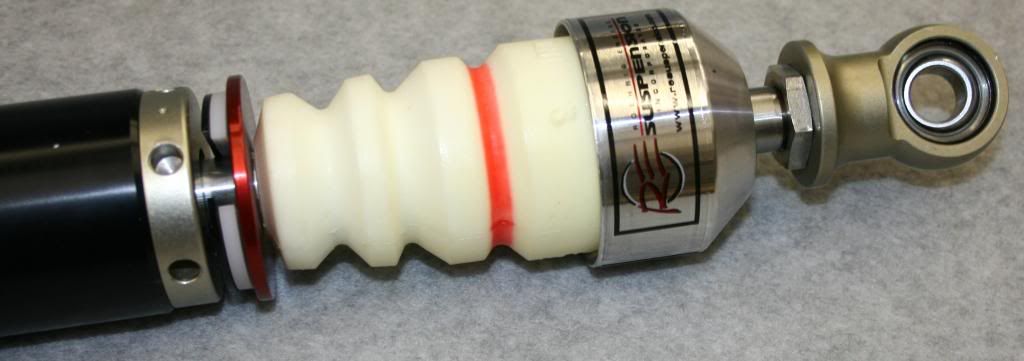

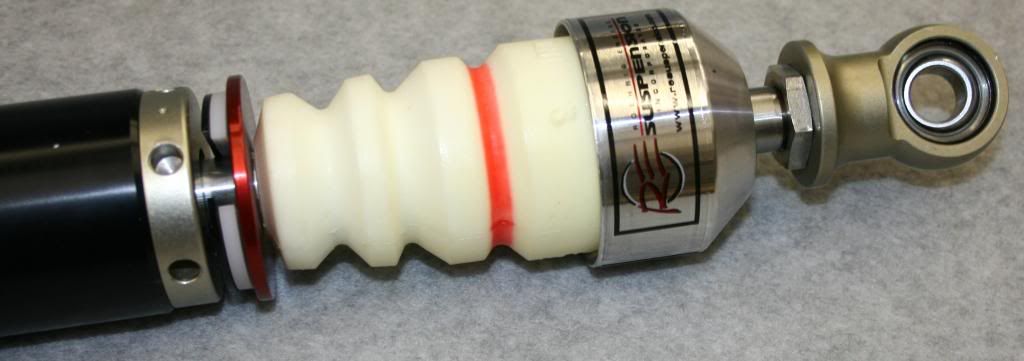

Hrm .. just came across this .. is this how everybody does it ?

-

Yes is what I just described

-

Originally Posted by 7uptruckracer

throw it away to progressive

I haven't driven in a few years. I don't expect to get on the perfect solution right out of the box here.

I don't think I have enough laps under me yet to 'feel' what's going on with a stacked-spring / lockout setup. I've never been on a bump setup before; my plan is to run this for a bit just to get a feeling of how it works, since it's fairly cheap to do, then move on to something bigger and better later.

Thanks !

Last edited by RacerX10; 03-30-2016 at 05:55 PM.

-

Some shocks (bilsteins) use a circular clip to hold the shock rod guide in.The bump stop can shove the guide in to the shock body.They make special caps that set against the body to prevent this.Make sure you won't have this problem with what ever brand of shock you are using.I use a plain spring seat on the bottom. I just get one that does not have the slot cut in it to slide over the shaft.You remove the shock heim to install it.We had better luck not trying to over think the bumpstop.Just make a change ,try it ,then just say" ok that is what it does".

-

Originally Posted by RCJ

Some shocks (bilsteins) use a circular clip to hold the shock rod guide in.The bump stop can shove the guide in to the shock body.They make special caps that set against the body to prevent this.Make sure you won't have this problem with what ever brand of shock you are using.I use a plain spring seat on the bottom. I just get one that does not have the slot cut in it to slide over the shaft.You remove the shock heim to install it.We had better luck not trying to over think the bumpstop.Just make a change ,try it ,then just say" ok that is what it does".

Thanks RCJ, that's kinda my plan. Try and and see what it does.

I have Integra IDA shocks. I'll take a look at the end and make sure nothing terrible is going to happen at the bottom of the shock when it hits the bump.

-

Originally Posted by 7uptruckracer

Take COT bump, get peanut butter, fill with peanut butter, give to your dog as a new Kong toy....problem solved..... It's best to use in a cup set cup on top of machine washer and using a washer on top of COT bump and use packers to adjust but in all honestly throw it away to progressive

another very informative post from you , I guess my problem was the peanut butter, thanks for sharing your vast knowledge....lol

-

Have you had your RF shock valving setup specifically for running on a bump stop?

-

Ok here is the informative part. Most COT bumps are very progressive. MAKE SURE you have an external travel indicator. So you know how much you are traveling, so you can determine wheel load. If you travel a medium 3" tall COT bump 1" its about 150# of wheel load if you travel an extra .5" for 1.5 total its 350. So in a very short distance it spikes tremendously.....A lot have gone to the lockout stack or a bump spring because a spring is linear by design. So once it engages determining load itsn't hard to figure out. Bumps especially a COT bump is very hard to run on dirt because you aren't on a smooth surface. You also have to be valved properly with rebound and bleed so it comes off the bump at the correct time and you have to rebound to control the additional load. Also the height of the bump and how much shock shaft you have before you engage it is critical. Know how much your ideal travel would be without the bump so you know how much you want to engage it. The Bump Cup you posted lets the bump expand and load more consistently and also helps wear being it can't expand but so far outward before it hits the bump cup. The washer on top of the cone gives it a consistent surface to bump against and the packers or shims help control engagement height. So like I said Fill it with peanut butter and get something that is going to give you consistent results with your program. You can't just throw a bump onto a spring without doing all the math to know what you are changing and where. If you have a particular goal in mind post it and post your setup and posters on here will be more then happy to help you work it out. Remember aero is big these days as well as camber thrust.

-

Originally Posted by Matt49

Have you had your RF shock valving setup specifically for running on a bump stop?

I haven't had anything specific like that done to the shock. I bought it (them) used as a set. What's special about the valving for a Integra IDA on a bump stop ? Again, keep in mind I'm running to "make the show" .. I'm not trying to light the world on fire yet. Will I even be able to notice any difference in a shock valved for a bump ?

Sure hope that doesn't sound contrary .. just trying to learn something

-

Originally Posted by 7uptruckracer

Ok here is the informative part. Most COT bumps are very progressive. MAKE SURE you have an external travel indicator. So you know how much you are traveling, so you can determine wheel load. If you travel a medium 3" tall COT bump 1" its about 150# of wheel load if you travel an extra .5" for 1.5 total its 350. So in a very short distance it spikes tremendously.....A lot have gone to the lockout stack or a bump spring because a spring is linear by design. So once it engages determining load itsn't hard to figure out. Bumps especially a COT bump is very hard to run on dirt because you aren't on a smooth surface. You also have to be valved properly with rebound and bleed so it comes off the bump at the correct time and you have to rebound to control the additional load. Also the height of the bump and how much shock shaft you have before you engage it is critical. Know how much your ideal travel would be without the bump so you know how much you want to engage it. The Bump Cup you posted lets the bump expand and load more consistently and also helps wear being it can't expand but so far outward before it hits the bump cup. The washer on top of the cone gives it a consistent surface to bump against and the packers or shims help control engagement height. So like I said Fill it with peanut butter and get something that is going to give you consistent results with your program. You can't just throw a bump onto a spring without doing all the math to know what you are changing and where. If you have a particular goal in mind post it and post your setup and posters on here will be more then happy to help you work it out. Remember aero is big these days as well as camber thrust.

Thanks 7up. If it really is that complicated, then I need to set it aside and go back to a standard 375 spring on the right front. I doubt I have the manpower or willpower to get all that right.

-

I agree with 7up, you cant just throw it own and expect miracles, BUT, on a smooth , slick track, with the properly valved shock, it is bad fast. I no longer use the bump stop because of rough track conditions , im on a two stage set up now that uses two springs that jerry link at afco set up for me. its easier on equipment when it hits the high side. also you will notice a huge difference with a properly vaved shock that has a lot of slow speed ( shaft speed) rebound.

Last edited by fastford; 03-31-2016 at 07:39 PM.

-

I am not disagreeing with the other posters, but if you have the rebound and aren't getting too deep into the stop on a rougher track, you can run it and have some benefits.

Modern Day Wedge Racing

Florence -2

Atomic - 2

-

Originally Posted by MasterSbilt_Racer

I am not disagreeing with the other posters, but if you have the rebound and aren't getting too deep into the stop on a rougher track, you can run it and have some benefits.

What i was going to try was putting (keeping) a spring rubber in the 300#, yielding an approx 330 # spring when it's not smooth and slick, and pull that out when conditions warrant. Seems like that would keep it mostly out of the bump until you wanted it.

Am I crazy ?

-

Originally Posted by RacerX10

I haven't had anything specific like that done to the shock. I bought it (them) used as a set. What's special about the valving for a Integra IDA on a bump stop ? Again, keep in mind I'm running to "make the show" .. I'm not trying to light the world on fire yet. Will I even be able to notice any difference in a shock valved for a bump ?

Sure hope that doesn't sound contrary .. just trying to learn something

Not contrary at all...

7up hit on it. In most cases, you need the shock to have a different rebound profile than what works best for a standard spring or even for a dual-stage spring setup. I personally wouldn't waste the time with it unless your shock builder thinks you've got something that will work on the rebound side (high "zero" and usually a sharp nose).

To me, running a bump stop without making the other necessary changes (mostly shock valving) is like running E-85 without changing the carburetor. It may work if the carb wasn't right to begin with but if you don't know that, you're sort of guessing.

I've said this before and I'll say it again...building a good relationship with a good shock builder is the best time and money you will spend in late model racing. It isn't just about shocks. Most of the good ones know a great deal about vehicle dynamics and understand how to communicate with drivers.

Just my 2 cents...

-

Originally Posted by RacerX10

I haven't had anything specific like that done to the shock. I bought it (them) used as a set. What's special about the valving for a Integra IDA on a bump stop ? Again, keep in mind I'm running to "make the show" .. I'm not trying to light the world on fire yet. Will I even be able to notice any difference in a shock valved for a bump ?

Sure hope that doesn't sound contrary .. just trying to learn something

Its my understanding if the shock isn't valved for "Bumps" it'll land too hard and you'll get an instant, "PUSH". Secondly if the shock isnt valved to help keep it seated on the bump it'll lift off and you'll lose your drive. The car needs to land just so on the "Bump" and stay seated there. At least that is how I understand it.

-

Originally Posted by SuperEight

Its my understanding if the shock isn't valved for "Bumps" it'll land too hard and you'll get an instant, "PUSH". Secondly if the shock isnt valved to help keep it seated on the bump it'll lift off and you'll lose your drive. The car needs to land just so on the "Bump" and stay seated there. At least that is how I understand it.

Thanks for the explanation .. that makes a lot of sense.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

All times are GMT -5. The time now is 12:16 PM.

|

|

Senior Member

Senior Member

Bump Stop Help

Bump Stop Help

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Senior Member

Reply With Quote

Reply With Quote

Bookmarks